Solvent Recycling

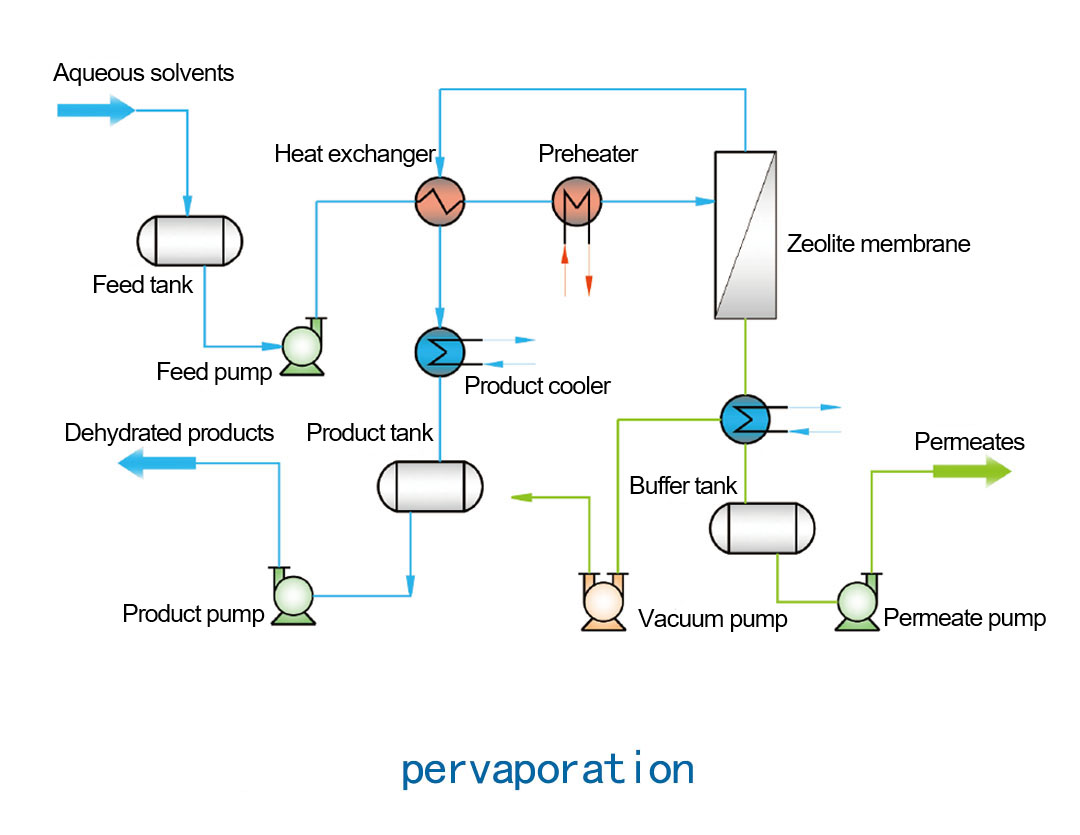

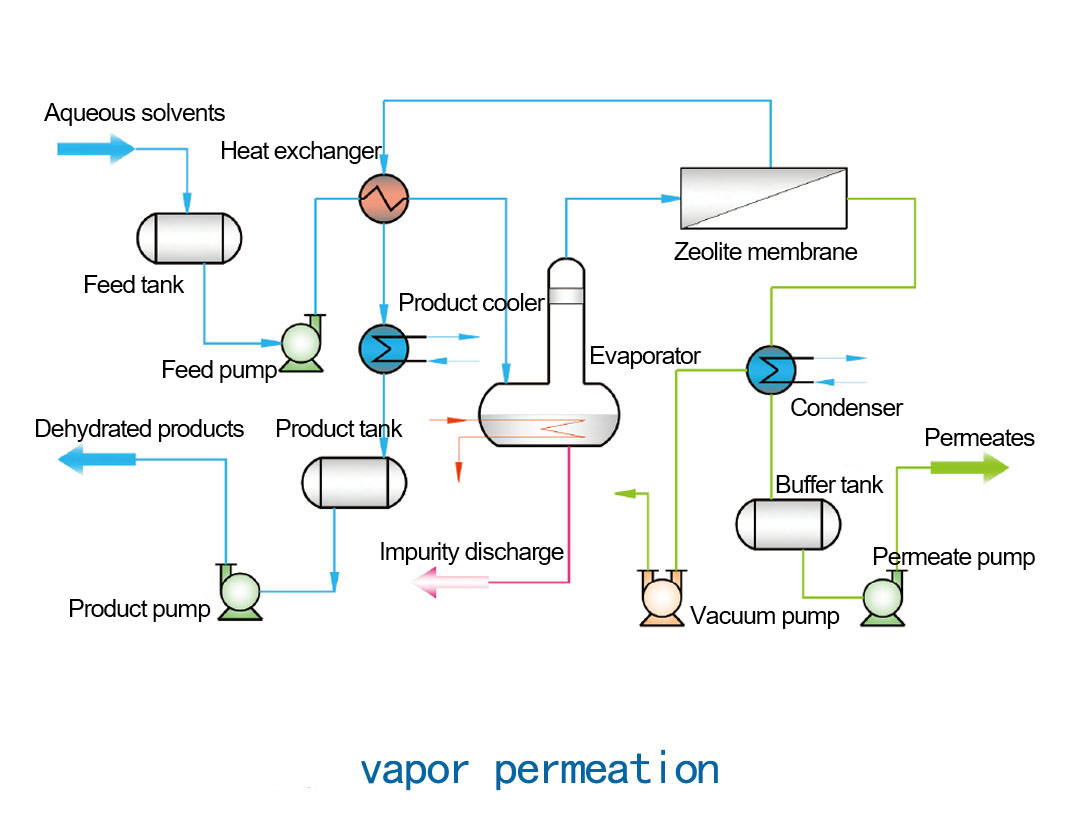

- Product details

- Table of parameters

● For the mother liquor recycling in the refining process of pharmaceutical industry, our patented technology, SISIR (Solvent & Intermediate Simultaneously Recovery process), can realize the simultaneous recovery of both solvent and high value intermediates.

● Our unique process, HiPLoT-PV (High Pressure Low Temperature Pervaporation), is suitable for t high efficiency and ultra-deepdehydrationof liquefied gas.

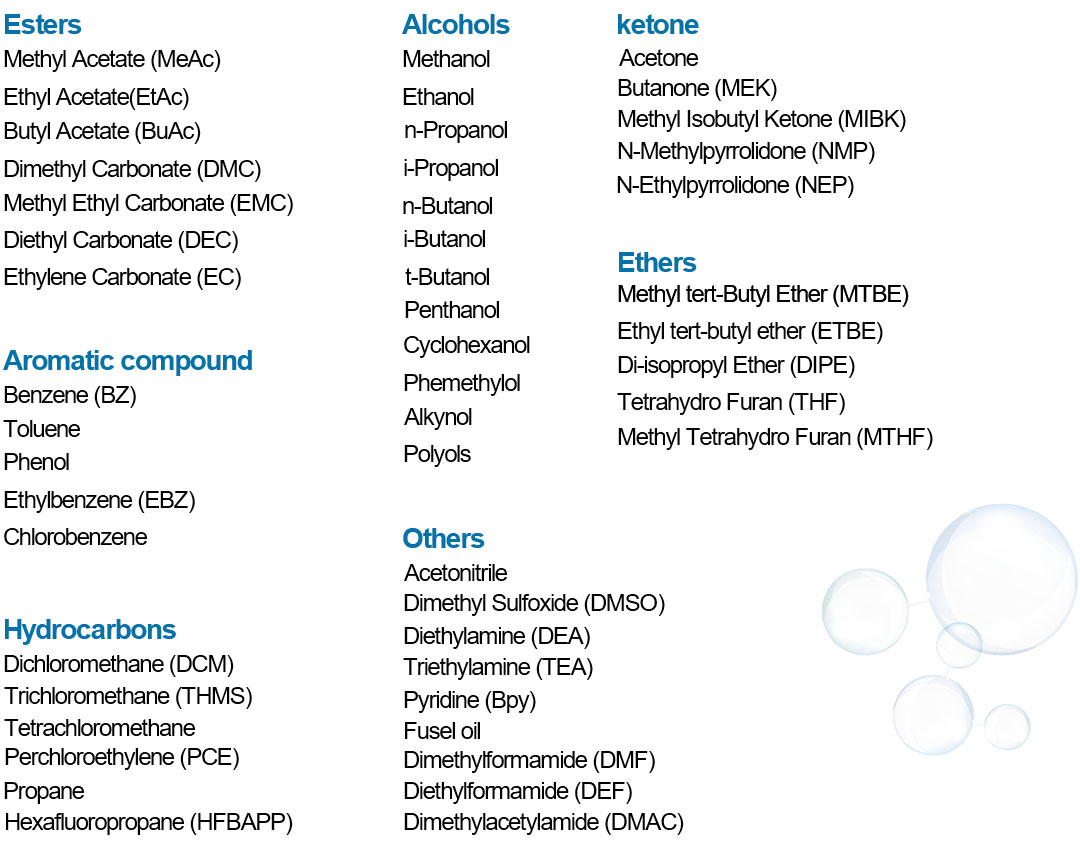

Application fields

Typical alcohol-water separation performance table

| Component | feed content(alcohols) | temperature(oC) | separationfactor | Throughput(kg/m2h) |

| Methanol | 90.0wt.% | 60 | >10000 | 0.62 |

| Methanol | 99.0wt.% | 100 | >1000 | 0.50 |

| Ethanol | 90.0wt.% | 60 | >10000 | 2.37 |

| Ethanol | 90.0 wt.% | 120 | >10000 | 4.62 |

| Ethanol | 98.0 wt.% | 120 | >10000 | 1.85 |

| n-Propanol | 90.0wt.% | 60 | >10000 | 2.69 |

| i-Propanol | 90.0wt.% | 60 | >10000 | 2.55 |

| n- Butanol | 90.0wt.% | 60 | >10000 | 2.80 |

| t- Butanol | 90.0 wt.% | 60 | >10000 | 2.66 |

| Glycol | 13wt.% | 120 | >10000 | 10.0 |

Specifications

| Item | Content | ||

| Feed conditions | Capacity | Annual output: 50 t ~ 300000 t | |

| Feed conditions | vaporphase / liquid phase | ||

| Raw material composition | Water content: 100pm-50wt% | ||

| pH | 6-8 | ||

| conductivity | <10 us·cm-1 | ||

| Other conditions | Free of substances that may contaminate the membrane(Hymater can provide solutions). | ||

| Operating conditions | operating pressure | Feed side | 0.1-1.4MPa.A |

| Permeate side | 100~8000Pa.A | ||

| Product parameters | operating temperature | 0-200℃ | |

| operating mode | BatchBatch-wise / continuous | ||

| Product index | Water content: could be as low as 5ppm | ||

| Single pass recovery rate | 99.8%~100% | ||

| Impurity introduction | No metal ions introduced. | ||

Typical case

i- propanol

| Item | Low pressure steam / yuan | Power / yuan | Circulating cooling water/yuan | chilled water/yuan | Sum |

| Distillation | 620 | 20 | 37 | --- | 677 |

| Adsorption | 350 | 60 | 20 | --- | 430 |

| Pervaporation | 87 | 26 | 4 | 9 | 126 |

1、Accounting example (2000 tons per year, the content of i-propanol increases from 85 % to 99.9 %)

2、The steam is RMB 200 Yuan/ t, the electricity is 0.7 Yuan/ kWh, the cooling water is 0.35Yuan/ t, and thechilled water is 1 Yuan/ t.

3、The data listed in the table are Yuan / t raw materials.

Acetonitrile

| Item | Low pressure steam / yuan | Power / yuan | Circulating cooling | chilled water/yuan | Sum |

| Distillation | 460 | 30 | 15 | --- | 505 |

| Pervaporation | 100 | 14 | 1 | 5 | 120 |

1、Accounting example (4000 tons per year, the content of acetonitrile increases from 80% to 99.5%)

2、The steam is RMB 200 Yuan/ t, the electricity is 0.7 Yuan/ kWh, the cooling water is 0.35 Yuan/ t, and thechilled water is 1 Yuan/ t.

3、The data listed in the table are Yuan / t raw materials.

Tetrahydro Furan

| Item | Low pressure steam / yuan | Power / yuan | Circulating cooling water/yuan | chilled water/yuan | Sum |

| Distillation | 400 | 25 | 20 | --- | 445 |

| Pervaporation | 60 | 12 | 12 | 6 | 90 |

1、Accounting example (800 tons per year, the content of Tetrahydro Furan increases from 80% to 99.5%)

2、The steam is RMB 200 Yuan/ t, the electricity is 0.7 Yuan/ kWh, the cooling water is 0.35 Yuan/ t, and thechilled water is 1 Yuan/ t.

3、The data listed in the table are Yuan / t raw materials.

10t/day Preparation of 99.5% anhydrous ethanol from 95% ethanol

| Item | Azeotropic distillation technology | zeolite membranetechnology | |

| Annual processing capacity | t/year | 3300 | |

| Steam | yuan/t product | 440 | 92 |

| circulating water | yuan/t product | 19 | 18 |

| electric energy | yuan/t product | 8 | 10 |

| Azeotropicentrainer | yuan/t product | 50 | 0 |

| Depreciation of membranes (5 years) | yuan/t product | 0 | 58.8 |

| Depreciation of equipment (10 years) | yuan/t product | 40 | 31.5 |

| Unit product operation cost | yuan/t product | 557 | 210.3 |

| Total operating energy consumption (10,000 yuan / year) | 183.8 | 69.4 | |

| Total income (10,000 yuan / year) | 114.4 | ||

| Price of equipment (10,000 yuan) | 130 | 200 | |

| Increase in investment (10,000 yuan) | 70 | ||

| Payback period of investment | 223 | ||